What is Engineering Risk Management?

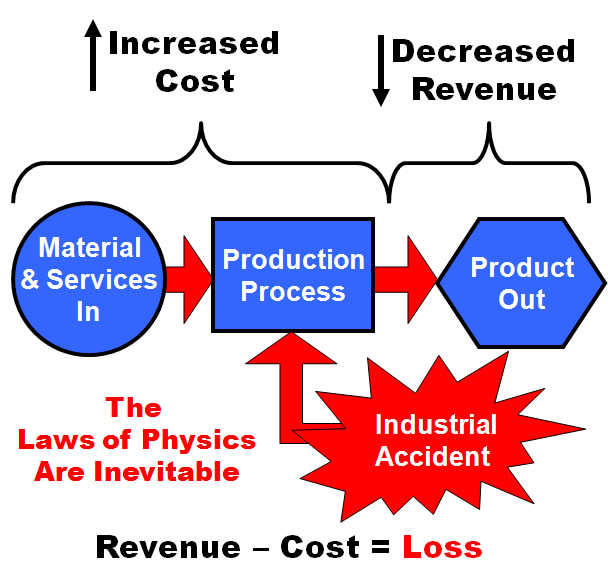

Industrial accidents can be very costly both monetarily and in terms of human suffering. A major industrial fire can quickly turn profits into losses. Events such as these can come on without warning and have a devastating impact. While totally eliminating the risk of such an event is not possible, greatly reducing the probability of such a serious accident is an obtainable objective. Reducing risks of this nature is sound business practice. All industrial producers come to this conclusion in the course of their business development. The only question is whether they do so before or after a major industrial accident.

The challenge is to get the maximum amount of risk reduction for the least amount of cost. This is where the expertise of Salus Engineering International can have a major positive impact on those seeking risk reduction for their industrial process.

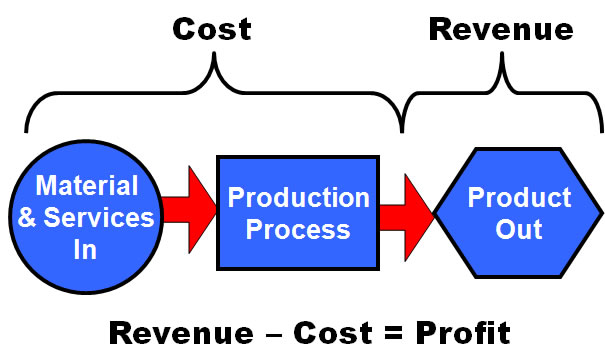

Basic Production Process

Breakdown of Production Process

All industrial producers will have a plan in which they attempt to minimize cost and maximize revenue in a way that will most effectively enhance the profit picture. All plans have some contingencies. However, major industrial accidents are not something that can be taken into account within the overall business plan. This is how Salus Engineering’s engineering risk management adds value to a company, by enabling them to control and avoid the costly unplanned and unanticipated consequences of a major industrial accident.

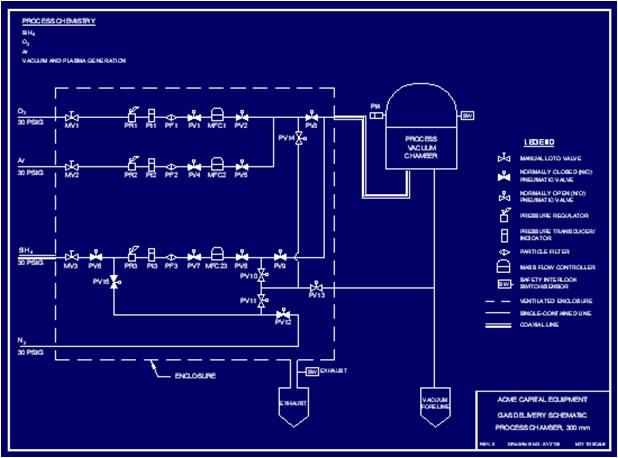

Engineering Analysis of Faults and Failures

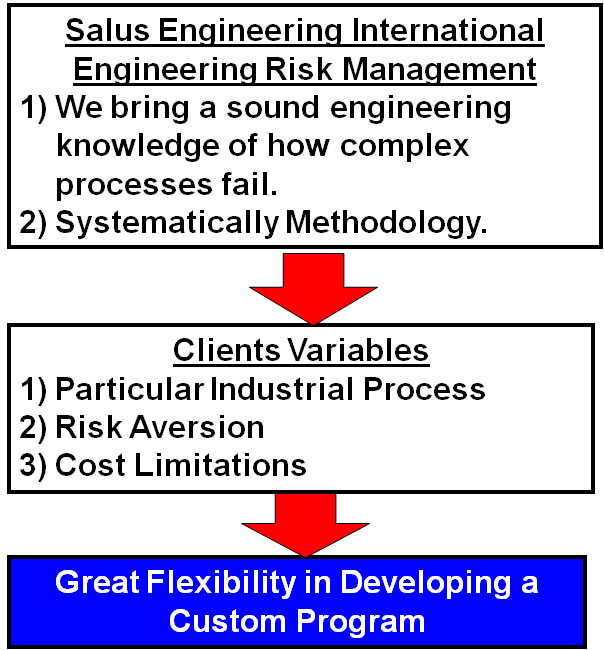

While the decision to implement an engineering risk management program is a strategic business decision, the program itself comes down to sound engineering analysis. The reality is that the more complex an industrial process is, the more potential for serious faults and failures and the more difficult it becomes to determine potential sources of serious incidents. This is a key area where Salus Engineering International can add value. Our interdisciplinary engineering team of experts have years of training and experience in how complex industrial systems can fail and cause serious problems. Industrial fires are always a major concern however they are not the only source of potential trouble. A release of toxic chemistry or a mishandling of other types of energy can have an equally devastating impact. The particulars of a risk reduction program will vary based on the specific industrial process. But the need for expert analysis is the underlying constant – and this is what Salus Engineering International provides.

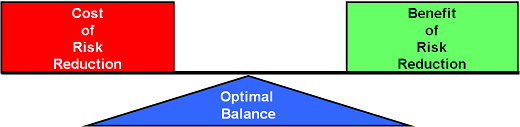

Optimizing Risk Reduction

The challenge is not to obtain risk reduction at any cost, but rather to obtain cost effective risk reduction. This requires striking a balance between reducing risks and the cost associated with that risk reduction. Many of the critical factors which will determine what the ultimate balance between these opposing factors will be are determined by the manufacturing company itself. These will include things such as the company's aversion to risk versus its risk acceptance and the nature of its production processes. By having a close collaboration with the industrial manufacturer, Salus Engineering International can help them obtain maximum risk reduction for the amount of effort they choose to put into controlling their business risks from these type of unplanned events. The expertise of Salus Engineering International can greatly assist the industrial manufacturer in obtaining maximum risk reduction for their efforts.

Customizing Engineering Risk Management

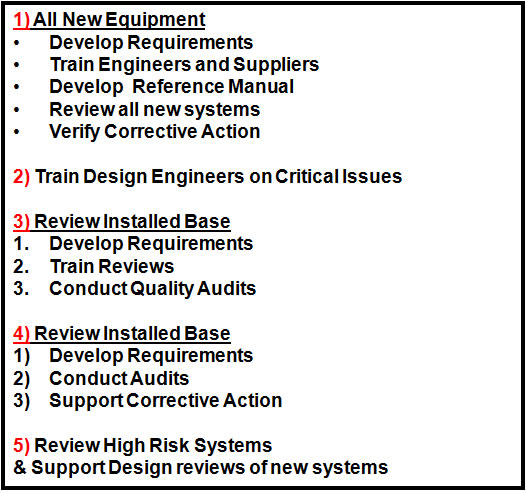

A customized program based on the nature of a company's production process and the balance they wish to strike between risk reduction and cost. By working within these parameters Salus Engineering International can tailor a program to suit your needs.